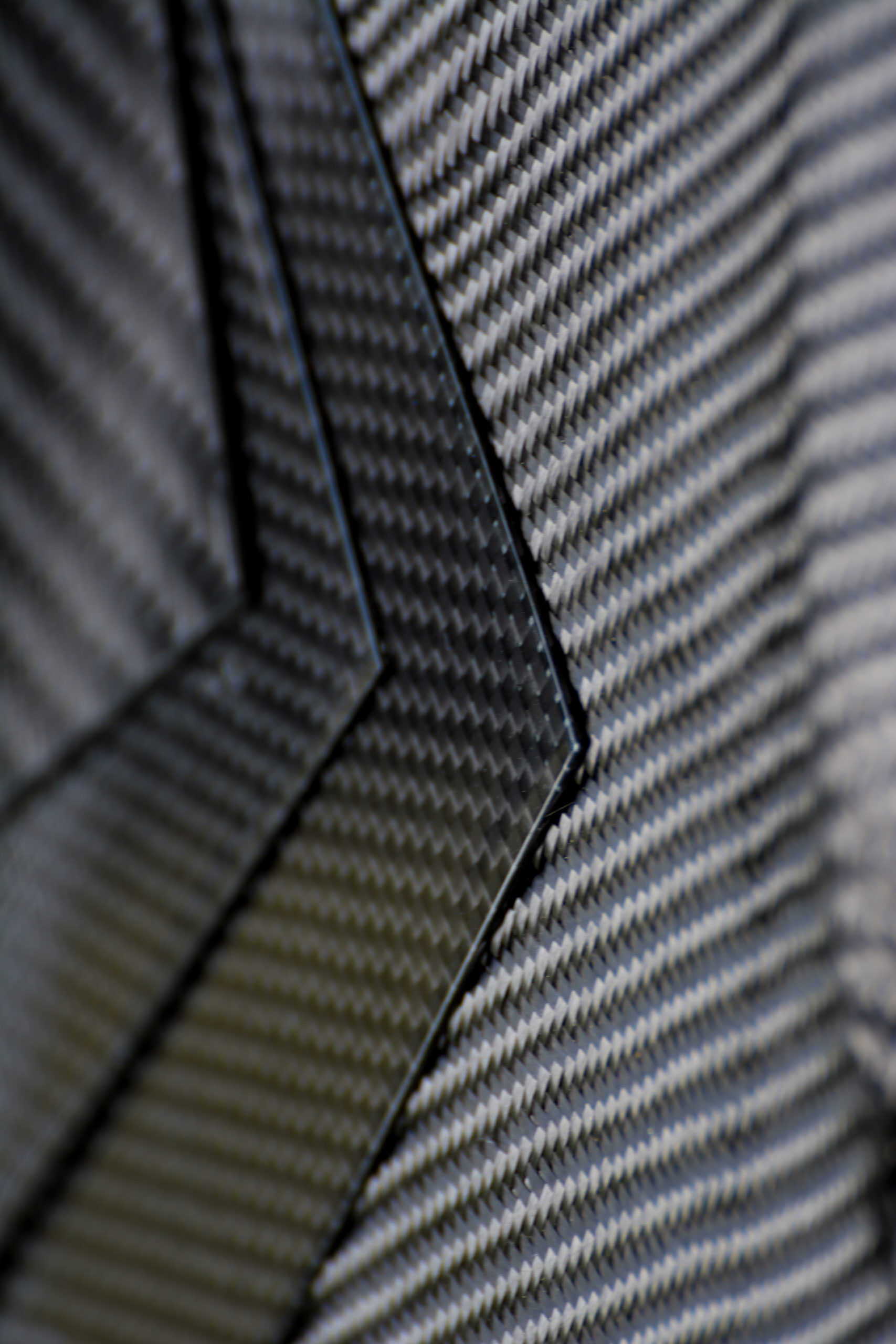

Southwest Composite Works designs, prototypes, and manufactures custom carbon fiber composite parts for clients in recreation, healthcare, industry, aerospace, and more.

Whether you’re looking for prototypes or full-scale production, we can custom-build lightweight, high-strength components to meet your demanding performance goals.

Built Light. Built Strong. Built Custom.

Why Choose Carbon Fiber Composite Parts

Carbon fiber composites provide an exceptional balance of strength, stiffness, and reduced weight. Parts made from carbon fiber have significantly higher strength-to-weight ratios, as well as higher stiffness-to-weight ratios than metals like steel or aluminium. Carbon fiber is significantly stronger than most materials at the same weight.

Carbon fiber composites also resist corrosion, fatigue, and temperature variation, giving those parts a longer service life, as well as more consistent performance in challenging environments. This makes carbon fiber parts ideal for applications where weight reduction and durability directly improve performance.

Our Custom Manufacturing Process

We manage every step of production in-house to maintain quality and efficiency. Our team will work with you, from concept to production, to ensure the manufacturability and reliability of your custom part.

Here’s what our manufacturing process looks like for carbon fiber composite parts:

Concept and feasibility review:

We review your custom part’s design and purpose, performance goals, and fabrication options to confirm it can be built efficiently, reliably, and to spec using carbon fiber composites.

Reverse engineering and CAD modeling:

Our team uses CAD modeling to digitize any existing part, and as needed, we will develop a new CAD model to ensure manufacturability in carbon fiber.

Tooling design and fabrication:

We use our in-house CNC machines to build the master patterns, molds, and fixtures that define the exact shape and alignment of every carbon-fiber part.

Layup:

Our expert technicians build the part layer by layer, placing sheets of carbon fiber into a mold, aligning each layer with the expected stresses in the finished part.

Curing:

Our technician heat the part to a controlled temperature to harden the resin and bond the fibers together, transforming the flexible layup into a rigid, finished carbon fiber composite part.

Inspection and finishing:

We perform thorough inspections for dimensional accuracy, surface quality, and structural integrity, followed by any necessary trimming, sanding, or surface treatments to ensure a polished, ready-to-use carbon fiber part.

How We Build: Proven Composite Manufacturing

We are experts in several manufacturing methods, depending on your part’s geometry, and your performance requirements:

Compression Molding

Custom heated steel dies and high mechanical pressure are used to form carbon fiber material into precise shapes, in one efficient step. This is perfect for higher-volume parts that demand repeatable strength and minimal waste.

Autoclave Molding

Uses heat and pressure inside a sealed, pressurized oven (an autoclave) to produce high-grade strength, and smooth finishes. Ideal for high-performance, high-precision components.

Vacuum Bag Molding

Layers of carbon fiber are laid into a mold and sealed under a vacuum, compacting the fibers and resin evenly during curing. This is a cost-effective and versatile method for medium to large sized parts.

Oven Curing

Uses controlled heat to harden resin systems evenly across the part, improving strength, surface consistency, and bonding. Great for large, complex, or cost-sensitive projects that don’t require the extreme pressure of an autoclave.

Bladder Molding

Uses internal pressure from an inflatable bladder that expands as the resin cures, pressing the fibers outward for a tight, even finish. Perfect for seamless, high-strength parts with exceptional rigidity and low weight.

Our Design and Engineering Support

Our in-house engineering team collaborates with customers through every stage of design and development.

At Southwest Composite Works, we’ll proudly provide you with:

Feasibility Studies and Risk Analysis

We can evaluate whether your concept can be produced in carbon fiber, based on size, shape, and your performance requirements. Our team identifies technical challenges early, and proposes solutions to reduce cost, risk, and development time, before production begins.

Rough-Order-of-Magnitude (ROM) Pricing

We can provide a preliminary cost estimate, given the complexity, materials, and production volume of your project. We can help you to better understand the budget range before your final designs are complete, so you can plan your prototype and production stages.

Reverse Engineering of Existing Parts

We can turn an existing part or prototype into a detailed digital model for reproduction or improvement. Using 3D scanning, measurement, and CAD modeling, we can capture exact geometry and structure, and then refine the design for manufacturing.

Design for Manufacturing (DFM) Designs

We can optimize your part’s geometry, materials, and layup pattern so it can be efficiently built without sacrificing performance. This can help to reduce waste, simplify assembly, and ensure each part meets your functional and aesthetic goals.

We can work directly from your CAD models, drawings, or physical samples to deliver highly accurate, efficiency-driven, and production-ready designs.

Our Precision Machining and Tooling Capabilities

At Southwest, our facility features 3-axis CNC machining centers, so we can machine tooling, molds, and fixtures with great precision. Using advanced 3D CAD/CAM software, we’ll translate your digital designs into tightly controlled machining paths, ensuring accurate geometry, repeatable quality, and excellent surface finishes.

Our in-house team handles everything from the mold to the final composite part, which means we can maintain full control over lead time and consistency. This expertise is built on three decades of craftsmanship in patternmaking and mold construction, giving us the experience to reliably turn custom carbon fiber concepts into production ready parts.

3 easy steps for custom orders

How To Start Your Project

We want to partner with you to fully realize your custom carbon fiber project. Here’s how it works:

Share your concept, design, or sample.

Send us a sketch, a CAD file, or an existing sample. We can interpret your needs, ask follow-up questions, and help translate your idea into a manufacturable carbon-fiber part. Our team routinely works with clients at all stages, from rough early concepts to fully dimensioned engineering models.

We’ll do a feasibility review.

Our engineers will recommend the best materials and processes for your goals. We will evaluate your requirements for the part, identify which composite process best fits the design, look for any potential challenges, and recommend adjustments, all so your part can be produced efficiently and reliably.

You’ll receive a quote and a timeline.

After the review, we provide a clear, itemized quote that outlines tooling costs, part pricing, materials, and the recommended manufacturing method. We also give you a timeline based on the complexity of the design, the number of parts needed, and the type of tooling required.