Production focused support for designing and engineering carbon fiber parts.

Southwest Composite Works provides companies with design and engineering support for carbon fiber parts, from early concept all the way through production.

We can transform your early-stage ideas, existing parts, or rough sketches into production ready, high-performance CAD designs for carbon fiber parts.

Our engineering process helps you reduce risk, control cost, and accelerate development, so you can move confidently toward prototyping, tooling, and manufacturing.

Beyond carbon fiber, we manufacture with multiple composite materials, choosing the best material for every application.

Design & Engineering At Southwest Composites

Expertly engineered composite parts mean that your carbon fiber project will have fewer iterations, lower risks, and more predictable performance.

Our team focuses on manufacturability from the start, so your carbon fiber parts perform as intended, and can be produced reliably and efficiently at scale.

We’ll work with you to define your project’s requirements, to confirm feasibility, and to develop designs that fit your application and your manufacturing process.

At Southwest Composite Works, we’ll help you:

- Translate your concepts into production ready CAD

- Identify manufacturability risks early, through feasibility review

- Optimize your part’s strength, weight, and durability

- Manage costs with informed design and material decisions

- Support seamless transitions for prototyping, tooling, and production

Design-driven. Manufacturing-ready.

Our Process For Design & Engineering

Project Feasibility

Our engineers review your functional requirements, loads, tolerances, materials, schedule, and cost targets to determine whether carbon fiber is the right solution, and how to design it for production.

You’ll receive a clear feasibility assessment early in the process, along with a rough order-of-magnitude (ROM) cost estimate, so you can make informed decisions before committing time or budget.

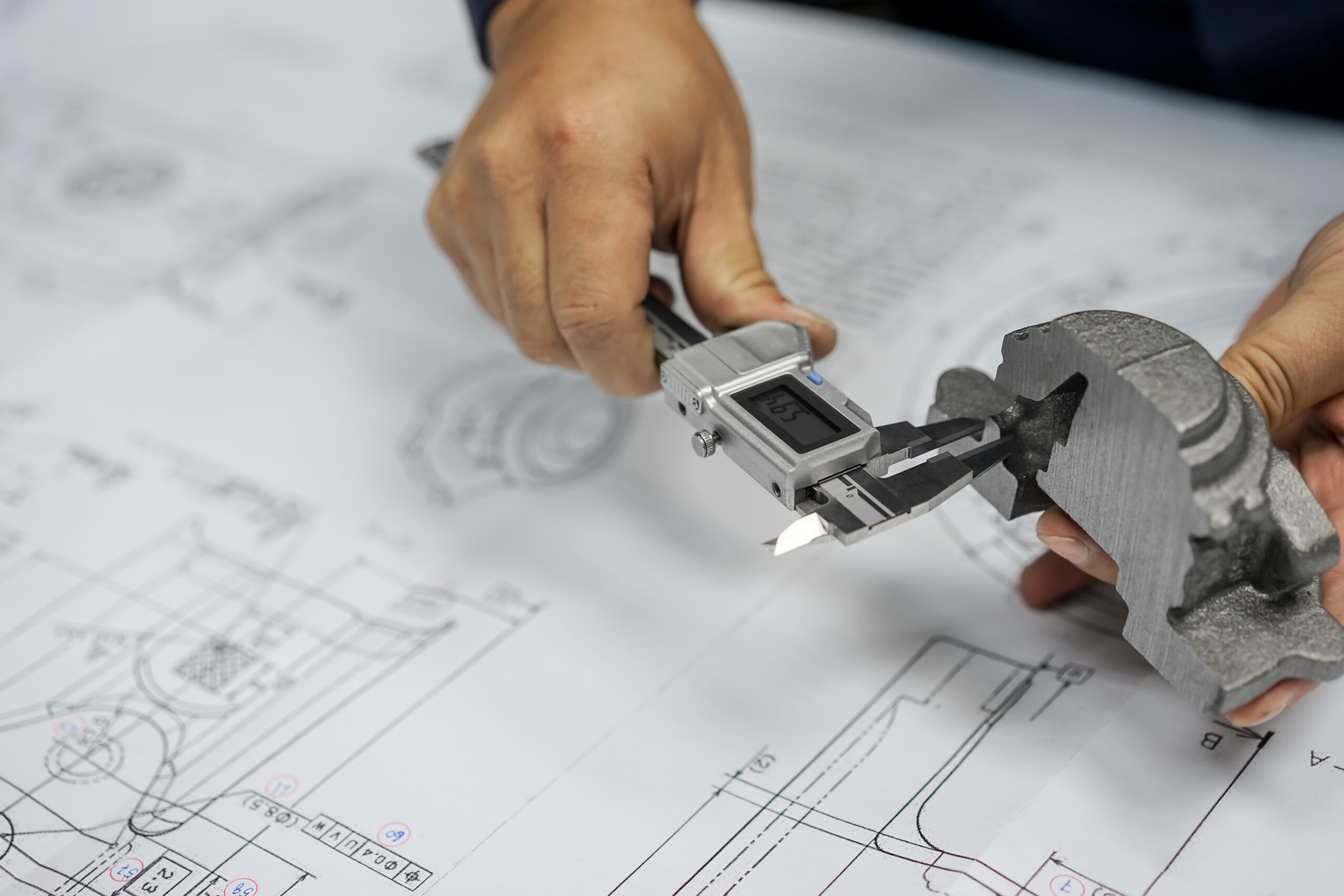

Reverse Engineering & CAD Modeling

If you’re starting with a physical part or sample, we can digitally capture its geometry to create an accurate, production ready CAD model. We can provide a reliable technical baseline for analysis, iteration, and manufacturing.

We’ll reconstruct or refine the design in CAD to ensure proper fit, functional intent, and manufacturability, accounting for material behavior, tolerances, and the composite process required to produce the part at scale.

Composite Tooling & Mold Design

We design composite molds, fixtures, and production tooling designed around your project’s geometry, material system, and manufacturing process, whether you’re producing prototypes or running full-scale production.

Our tooling is made to support consistent fiber placement, controlled tolerances, and strong process efficiency, which can help reduce cycle times, improve repeatability, and lower your lifetime costs.

Component Design

We engineer and refine composite components to meet defined performance requirements, while ensuring your part is efficient to manufacture, at production volumes.

Our design decisions are made with the realities of composite processing in mind: we’ll optimize for composite manufacturing your part’s fiber orientation, wall thickness, and geometry transitions.

What you can expect from design & engineering at Southwest Composite Works.

At Southwest, design & engineering is integrated into every project from the start, with a team-wide focus on building composite parts that meet your project’s manufacturing needs.

US Based Engineering and Production

All design, engineering, and manufacturing work is performed in the United States, helping us provide for quality control, communication, and continuity.

Cross Industry Manufacturing Experience

Our team brings experience from automotive, aerospace, industrial, defense, medical, and other applications, so our best practices are shared across use cases.

Integrated In-House Expertise

Our designers, engineers, and composite technicians work together under one roof, ensuring that all design decisions align with proven, real-world manufacturing limitations.

Cost Focused Design Decisions

We engineer every part to reduce tooling complexity, to minimize rework, and to shorten the path from design to production. That’s how we help you control your project costs and timelines.