We Are The Experts in Custom

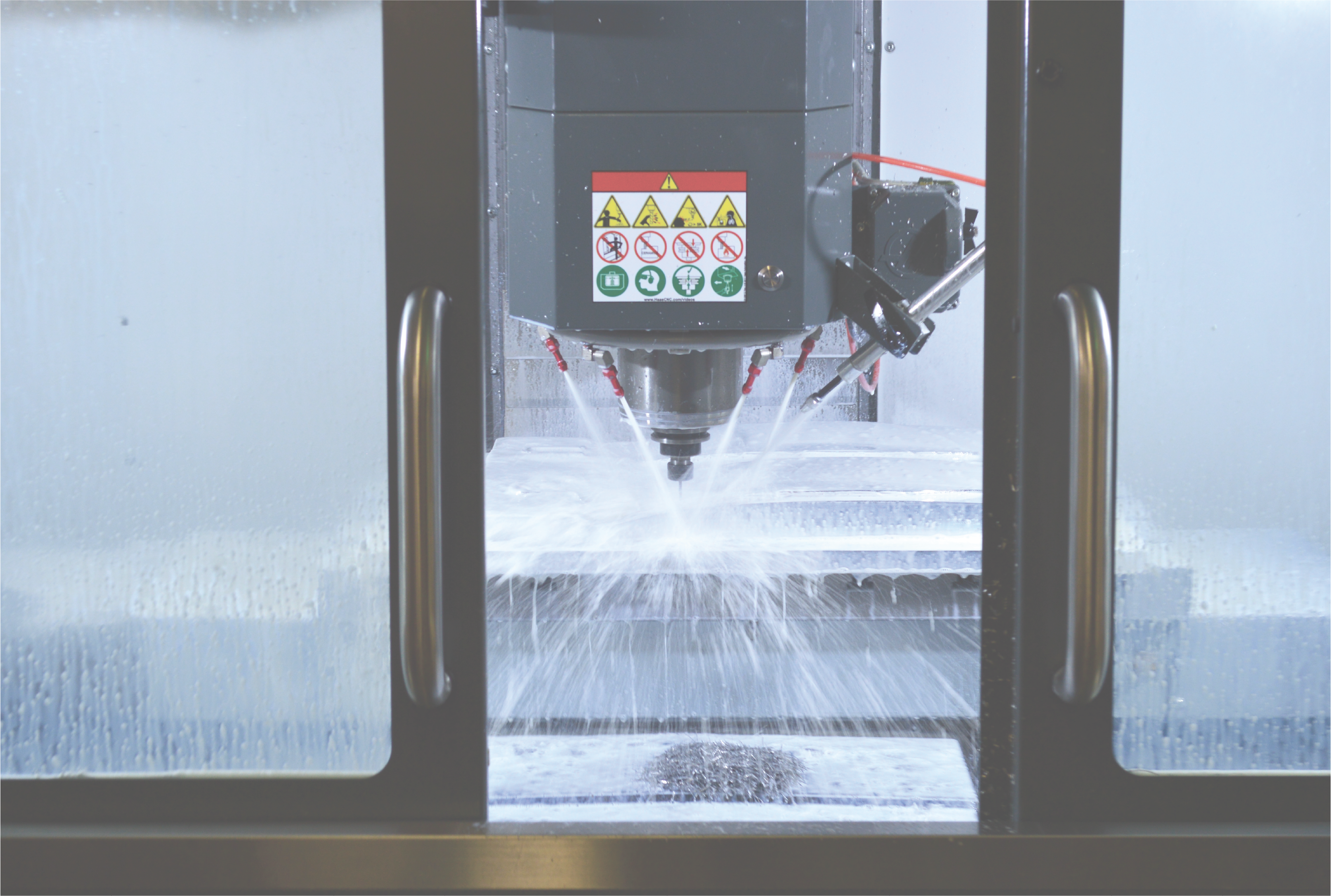

Southwest Composites utilizes 3 AXIS CNC Machining Centers to produce, prototype, or manufacture components to your exact specifications. Our Precision CNC machining also produces custom mold tooling and fixtures to meet our customer’s needs. The CNC machining of forgings, castings and raw materials is done with accuracy and precision at Southwest Composites. This is made possible through the use of 3D CAD/CAM software. We can expertly manage your project from start to finish.

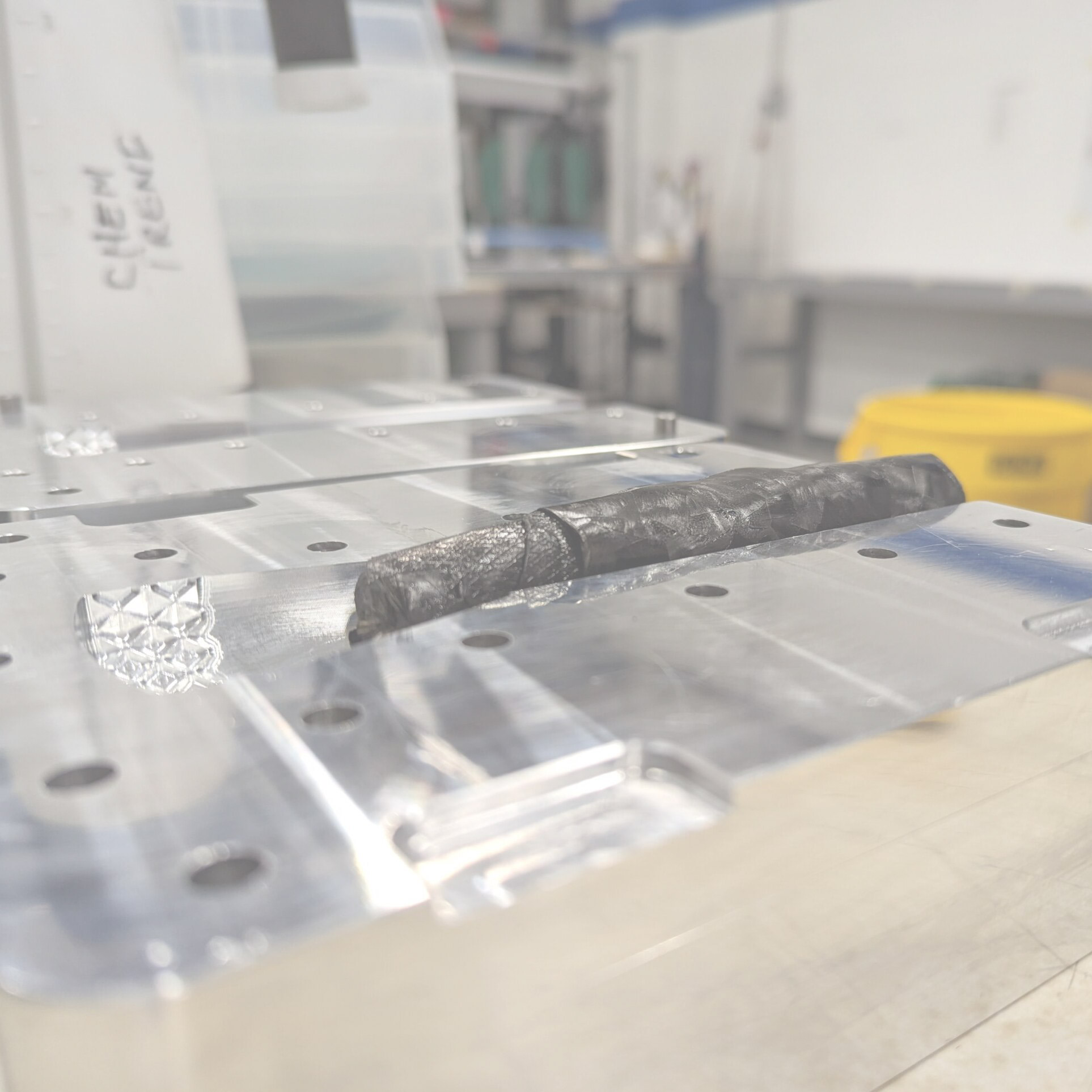

Advanced Mold and Tooling

Due to the foundry tooling and patternmaking experience from Southwest Composite Works parent company Southwest Pattern Works, we are experts in mold and tooling.

Custom Fixturing Solutions

A custom fixture is a device used to hold parts in a repeatable orientation for reliable measurement. They ensure that the part you are measuring is held in place.

Prototype Machining

Prototype CNC machining is a process used in producing one-piece or a small batch of a product before its preliminary production. The process is ideal for ensuring that t<span>he proposed process will meet all tolerances, volume, set-up cost, part cost, and lead time previously discussed.

CNC Production

NC stands for Computerized Numerical Control. It is a computerized manufacturing process in which pre-programmed software and code control the movement of production equipment. Our CNC operators can take a sheet of metal and turn it into an airplane part or fishing net.